TWO COMPANIES, ONE PASSION

What opportunities does the formation of UNITED MACHINING SOLUTIONS unlock? The UNITED GRINDING Group and GF Machining Solutions are creating a major player in the global market, with a presence in Asia, America and Europe, and close to customers everywhere – with customized technologies. But sheer size isn‘t the decisive factor, as Stephan Nell and Ivan Filisetti explain in this interview with “Motion”.

Text: Michael Hopp – Fotos: Oliver Oettli

Mr. Nell, Mr. Filisetti, with the formation of UNITED MACHINING SOLUTIONS you are setting out on a long journey together. How do you feel about that?

FILISETTI We at GF Machining Solutions feel extremely positive, mainly for three reasons: First, our products don't overlap but complement each other. This is extremely important, because it facilitates the integration between the two companies. Second, we are both Swiss companies, we share the same culture of precision and accuracy with a strong dedication to innovation. And third, we have a common understanding of what is important.

NELL All in all, I feel a bit like I am on a journey through time. We also used to belong to a larger group with different divisions. Our experience was that when we left that group, we could really focus on machine tools. And I hope that you will have the same experience. Now we can grow together, we can be a large international group, with the same mindset, as you said. We are now even more broadly positioned, remain competitive, and are better prepared for present and future challenges. I am sure that we will be very successful internationally and that we will make our customers even more successful – in line with our claim ‘United For Your Success’.

How long have you known each other personally? What was your first encounter?

FILISETTI We met each other seven years ago at the exhibition BI-MU in Italy. GF Machining Solutions was a customer of the UNITED GRINDING Group and we discussed operational topics related to a recent investment.

NELL I remember that we had a good connection right from the start and a lot in common, we talked about various topics. For example, things like: What is important to our customers?

FILISETTI During our first conversation, we emphasized the importance of supporting customers in all circumstances. In our business, mistakes can happen, but what truly matters is that we never leave our customers to face challenges alone. We stand by them until every issue is completely resolved. In fact, we've found that what begins as a ‘mistake’ can often be transformed into an opportunity for strengthening relationships and demonstrating our commitment to excellence.

Both of you seem to like what you do.

NELL Like? Love! If you start in machine tools, you have to love this business. Otherwise, you can't do it. It's a challenging business. You have a huge and fluctuating market. You must be a person that really loves the challenge. For me it's the most interesting industry one can work in. It’s not just our products, it's also our customers. They are so different. And that is what makes the job so exciting. I am sure we are both here because we love the business.

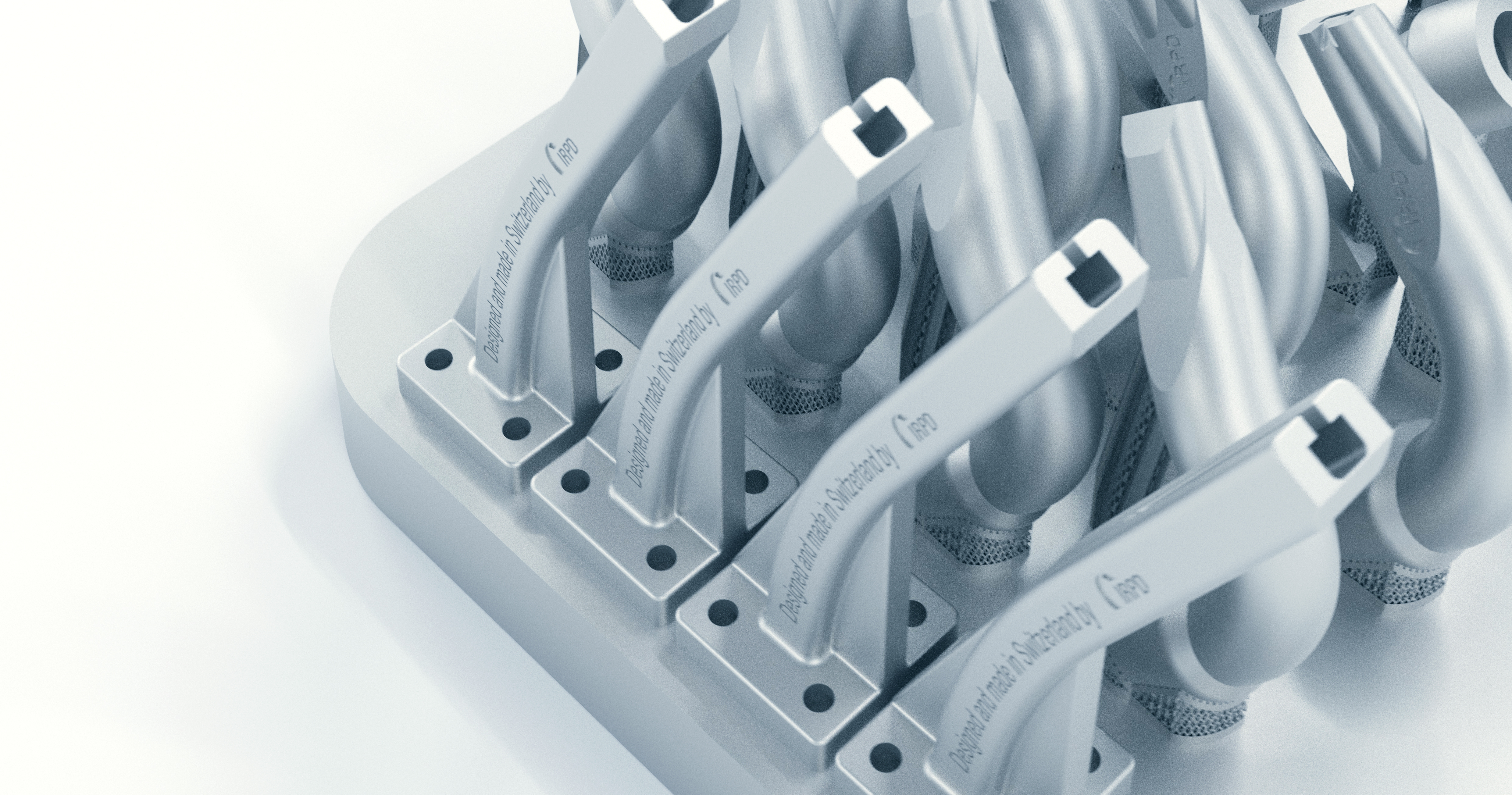

FILISETTI Exactly! Stephan and I both started in the machine tool business, my original specialization is the mold and die business. And here’s the thing: when you brush your teeth in the morning, you know that the toothbrush was made with a mold that has probably been produced with one of our machines. Our technology touches your everyday life in ways you might not realize. When you drive your car, you're surrounded by components that were cast in molds created with our milling or EDM machines. And when you fly, the turbine blades and blisks powering the aircraft engine were likely manufactured using a LIECHTI machine and wire EDM technology.That is fascinating.

Your products are essential for our daily lives.

NELL And it's a global business. You get familiar with different cultures all over the world. You learn more about a culture by doing business than by traveling as a tourist. And when you do business with a customer, it's a partnership for at least 20 years. It's very personal.

FILISETTI In our business, investments for a machine can go as high as 2.5 million euros and of course the customer wants to know who is behind the product that he buys. Our real work begins after machine installation. Customers frequently seek our application support and advice on optimizing their machining processes for efficiency and reliability. This creates a long-term partnership that typically spans many years.

How important is the “Swissness“ in your DNA? Is there still demand for European values in a changing world?

NELL Why are the Swiss and German machine tool builders still so successful today? It has to do with the way we educate our apprentices. Made in Germany, made in Switzerland – this still has a value. Most of our people work in Switzerland. And we are Swiss owned. So “Swissness” transports our values, like quality and precision.

It works as a symbol as well.

NELL Yes. But on the other hand, we are an international group. The sales numbers show that Switzerland is not our main market. The big markets are elsewhere. And that is why we need a culture that is not purely Swiss. In the U.S., we have to be a U.S. company, in China we have to be a Chinese company. We have to understand the customer. Swissness yes, but if you look at the distribution of our products, we are an international company.

Do you see it the same way, Mr. Filisetti?

FILISETTI Swissness certainly represents significant value in terms of culture and attitude in our daily work, but today GF Machining Solutions is an international company characterized by the speed of our Chinese colleagues, the business orientation of our American teams, and the precision and attention to detail of our European team.

Lately, the European and German mechanical engineering sectors have come under some pressure. What significance can sheer size have in this situation?

NELL I wouldn't talk about sheer size, but about global reach. There are not many companies like us which really have a strong presence in Asia, in America, and in Europe and which are so close to their customers. It's about understanding each other – that means not only the language but also the culture of our customers. We are medium-sized companies combined in a group. I hope that we can maintain this spirit of a medium-sized company. Because size doesn't tell you whether a company is successful or not.

FILISETTI What is much more important than the size of the new company is the fact that we address our customers‘ problems with very efficient solutions. There are huge companies that produce very simple machines in very high volumes. For us, it is more important to have a multi-technology approach regarding high-end applications. This is where we play; it is not only about the machine itself, but also the continuous support and innovation we provide to our customers.

NELL We don't just sell machines but also know-how. So, we think about which of our machines is best suited for the job and set up the entire process. We don't just sell off the shelf – we deliver customized solutions.

Experts sometimes lament a lack of innovation in the industrial space. Does this also apply to your industry? Or to put it differently: How would you define innovation?

FILISETTI We must differentiate between innovation and the incremental improvement of a product. For me, innovation is ‘a new invention’, meaning something that was not available before! Continuous improvement is good, it is even necessary, don't get me wrong. But what really counts is something that didn't exist before that changes the paradigm for our customers, and brings them to another level of competitiveness; in German we call it ‘Quantensprung’. In this regard, we can be proud of ourselves – we have at least ten kinds of developments accomplished in the past years that are still unique! This is the spirit we want to keep in the future: make a difference in the market with pure innovation.

NELL The way you think about innovation is in line with my own ideas. Progress requires continuous investment over years.

FILISETTI As a customer, I remember when STUDER introduced a real innovation in 1998. That year I was so proud to be the first to buy a STUDER S40, a cylindrical grinding machine with the first threading function available on the market. A pioneering achievement at the time! I think with this STUDER opened completely new possibilities in cylindrical grinding.

NELL It is very charming when Mr. Filisetti tells us that STUDER changed the world!

What strategies ensure that your machines meet both current and future needs?

NELL We future-proof our machines by adhering to tomorrow's European Union standards and regulations today. When a customer buys a machine, he or she can be sure that we will be able to meet the requirements in the future. Imagine buying a machine and then years down the line, being told that you can no longer use it because of new regulations or connectivity. That won't happen with our machines, we are prepared. The size of our new group helps, too. By harnessing our combined strengths, we are pioneering innovation and realizing the full potential of collaboration.

Another area that makes machines future-proof is sustainability.

FILISETTI In the last three years, we've worked hard to implement a meaningful sustainability program that brings real value to our customers. Our focus has been reducing energy consumption in our machines – including electricity and compressed air – while eliminating energy waste. To validate these efforts, customers who purchase our new products receive a certification documenting the energy savings. This can be up to 50% compared to the previous machine models. All measurements are conducted according to ISO standards.

Sustainability can be achieved at different levels…

FILISETTI Absolutely! For example, our plant in Biel achieved 90 percent carbon reduction by 2022 compared to the 2020 baseline. But again, it is also important to understand what benefits sustainability can bring to our customers! If you can produce a part in half the time, that is also a great achievement in terms of sustainability.

NELL The greatest contribution to sustainability lies in the machines themselves. With our machines the customer can produce faster, more accurately and efficiently. A good comparison is the diesel engine. The old diesel engine had 80 horsepower and consumed 15 to 20 liters of diesel. Now we have 200 horsepower, and the average consumption is four or five liters. This is good for the environment and would not be possible without modern machine tools. There are so many more examples. If you look at the cans used by soft drink manufacturers: They are made of very thin metal now. This is possible because machine tools like ours are capable of producing tools with high precision, and the use of these tools reduces the amount of sheet metal by half. And this has an impact.

Is precision still a domain where companies can carve out a competitive edge?

FILISETTI I'm not expecting that in precision we can achieve a quantum leap – we can always improve a little further, but there are physical limits. At this level, further enhancements would yield imperceptible gains. In my opinion, the critical focus lies in reliably maintaining this precision in a sustainable way – particularly within automated manufacturing processes.

How important are automation and digitalization?

FILISETTI First of all, when we talk about digitalization, we talk about tons of data. It's essential to recognize that many of our customers are not large corporations—we often serve niche businesses, typically teams of 10 to 12 highly specialized experts. These kinds of customers don't have time to check a lot of data. If we gave them a complex system with five screens and tons of data in charts, it wouldn't work. What's important for them is a reliable, predictable system with clear and limited key performance indicators.

NELL People are dreaming about the potential we might have in digitalization. But it is not a question of whether or not to invest in digitalization. We are simply doing it because it is necessary. But it is much more about what the customer needs. In the early days of digitalization, the industry did everything that was possible. Five screens showing everything that can be measured. But that is not the point. Where is the benefit? We always have to ask ourselves: What kind of digital or automation solution fits the specific customer's need? And then we tailor the system accordingly. If we are not providing value to our customers, they are not willing to pay for it.

Is there still untapped potential in customer service?

FILISETTI Of course, you can always improve Mean Time To Repair and Mean Time To Install – it's a continuous journey. But honestly, even maintaining the current level is challenging. Many highly skilled experts are nearing retirement, and their knowledge must be passed to the next generation. That's a major task: you invest today to see the payoff in three to five years.

NELL One might think that merging companies would allow us to cut costs when it comes to Customer Care. But that is not the case. The machines we produce are much too complex for that. When we send a technician to a customer, he or she must be an expert.

While many manufacturers of consumer goods pursue an umbrella brand strategy, you want to emphasize the well-known local brands. Why is this the more successful approach?

NELL Our brand companies have a long tradition and each brand stands for its technology. Many of our brand companies have more than 100 years of history in their business. This is a huge value we have to safeguard.

FILISETTI They are pioneers. That's worth a lot.

How do you assess the mood among your people regarding this important strategic step?

FILISETTI I travel extensively to communicate our strategic vision and the opportunities it presents. With a global workforce, ensuring alignment and shared purpose across the organization is very important. A colleague once shared a poignant insight: ‘What matters most is knowing the company will endure beyond my career.’ This sentiment resonates deeply. I see it as my task to safeguard our long-term viability and legacy.

NELL Neither of us is directly involved in building or selling the machines. Every process, every innovation, is driven by our employees – they are the heartbeat of this organization and our most profound responsibility. There are only two things you cannot copy in a company: a motivated team and brand value. Buildings, machinery, and technology can be acquired, but not culture and tradition. In the machine tool industry, cyclicality is a given, but important is long-term success. And in five or ten years from now, when we meet again at this table, people will have decided whether we have done a good job.

FILISETTI This is very important. Daily operations can be optimized overnight, but long-term strategy requires unwavering focus. A clear vision isn't just essential; misalign it, and the journey ends before it begins.

The day after closing: What were the first steps? What was on the top of your agenda?

NELL Our first priority was clear communication with our employees. We held a live-streamed worldwide meeting to explain the situation in detail. As I emphasized earlier: The most important asset we have are our employees.

FILISETTI The day of the closure marked the final page of one chapter in the history of our company. It is crucial to establish a common mindset as we transition fully into UNITED MACHINING SOLUTIONS as UNITED MACHINING. Our path forward remains unwavering: we will focus on the market, on our customer's trust through quality, and deliver excellence without compromise. While synergies and collaborative advantages will naturally unfold, our priority is clear. We will sustain our market leadership and pursue our goals.

NELL For the majority of the people in the group, there won't be any changes. They have the same customers, they have the same goals. The real challenge is …

FILISETTI … is the market.